Our 3D substrate combines multiple PWB and material technologies. We provide substrates that apply a variety of technologies to realize miniaturization and multi-functionality of modules.

Feature

Variety of technologies to realize miniaturization of 3D substrates.

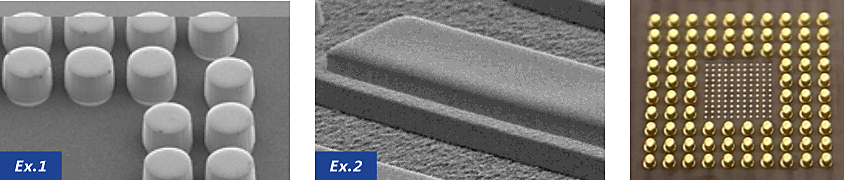

Cu Bump Formation

Support various shapes with excellent copper plating technology

(Ex.1) Height 180um / Size φ250um

(Ex.2) Height 20um / Size 0.15×9.0mm

(Ex.1) Height 180um / Size φ250um

(Ex.2) Height 20um / Size 0.15×9.0mm

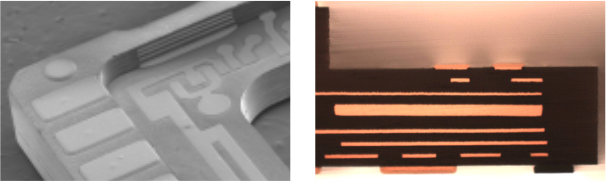

Cavity Structure

Achieved by high-precision milling process

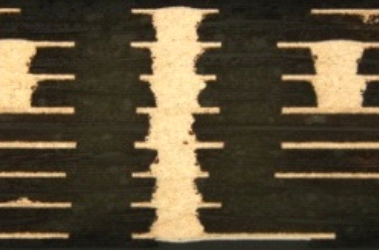

Stacked Via for Wire Bonding

・Ensure flatness on stack vias

・Wire bonding is available

・Achieves compactness and space saving

・Wire bonding is available

・Achieves compactness and space saving

Application

Various Modules / Sensor / LED