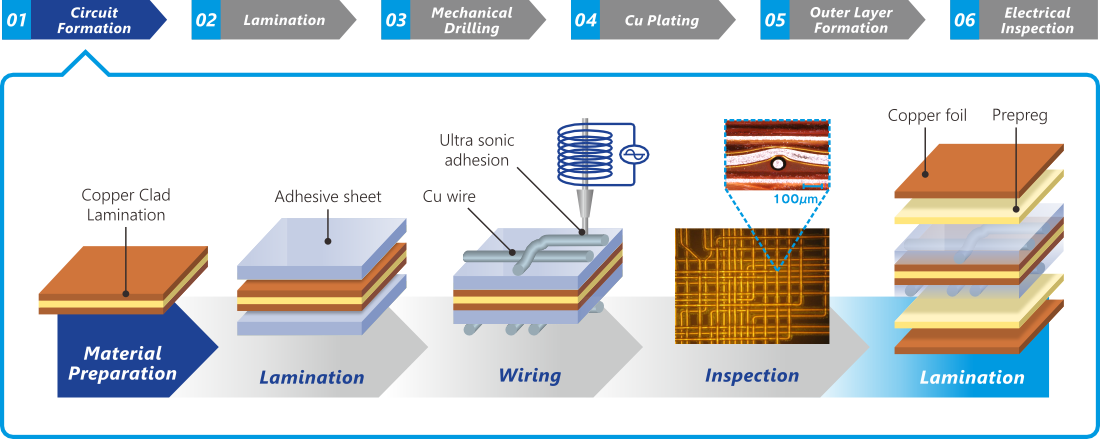

Multi-Wiring Board (MWB) is our unique PWB technology that uses insulated copper wires for circuit formation and does not generate waste or waste liquids as with the standard print-and-etch process making it a more environmentally friendly.

Feature

Copper wires are insulated with polyimide allowing for the crossing over of circuits. This promotes a higher density layer and resulting in an overall reduction in total layers.

High degree of flexibility in the wiring design and ability to achieve equal length wiring.

The benefits of the uniform copper wires can be seen in the reduction of electrical performance variation. The stable performance is observed not only among products from a single lot but also in different production lots.

Application

Probe card / IC tester

Our MWB provides a high level of specification that usual PWB cannot exert.

Please refer to “Do you know MWB?” for details